Ansys

ANSYS FEA & Structural Analysis[edit | edit source]

You want to conduct structural analysis on your parts but don't know where to start in the rabbit hole of ANSYS FEA, this page is for you. Before you can dive deeper into finite element modeling, you must first understand the basics of deformable bodies and material science. More specifically, how stress concentrates around features in your parts and predicting potential failure modes.

Introduction into Stress[edit | edit source]

What is Stress?

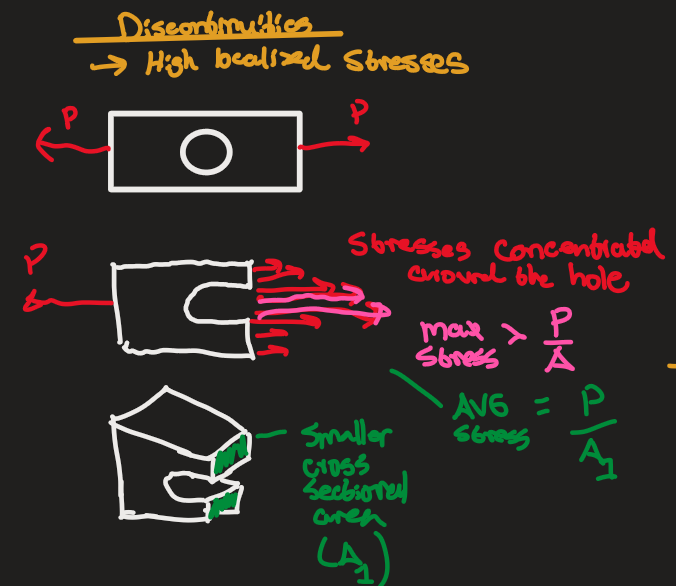

At a microscopic level, the bonds between atoms and positions of molecules within a material are disrupted when a force is applied. The atoms and molecules attempt to resist this change in motion and this internal resistance is stress. Now this stress flows through a material at a macroscopic level as stress lines, concentrating around discontinuities and features that break the consistency of the part. These discontinuity features usually include holes, fillets, chamfers, edges, etc.

Why does Stress Matter So Much?

At a basic level, an engineer's goal is to reduce stress and stress concentrations in a part to decrease the chance of premature failure and potential catastrophic damage. With given load cases (applied forces and moments) and boundary conditions (given constraints and engineering model assumptions), you can use finite element analysis software such as ANSYS to ensure stress is concentrated more evenly and eliminate failure modes from your design.

Types of Stress

Stress Concentration Factors & Graphs

Stress Factors

Stress Transformation - Mohr's Circle

Ductile Material Failure Theories[edit | edit source]

Tresca Failure Theory

Von Mises Failure Theory (Bread & Butter for GTMS related work)

Tsai-Hill Failure Theory

Gurson Failure Theory (Only for microscopic voids within material)

Brittle Material Failure Theories[edit | edit source]

Rankine Failure Theory

Coulomb-Mohr Failure Theory

Modified-Mohr Failure Theory

ANSYS Finite Element Analysis[edit | edit source]

For getting comfortable with ANSYS, the ANSYS youtube channel and website contain great introductory guides for creating first Workbench file and simple ANSYS mechanical setup for creating a mesh, constraints, forces, and solutions.

Joints[edit | edit source]

Contacts[edit | edit source]

Supports[edit | edit source]

Modeling Physical Bolts[edit | edit source]

If you are ever modeling physical bolts in ANSYS Mechanical for reasons such as analyzing applied forces, moments, preloads, etc, you must use the Hex-Dominant Mesh Method. This method creates mesh elements that propogate radially outwards from the center axis of the part rather than a seemingly random assortment of tetrahedrons.

Ensure when modeling bolts that you are using accurate material properties associated with it. Example: Don't use aluminum material for bolts that are actually steel and will undergo cyclic loading for fatigue.