Suspension Handbook: Difference between revisions

JosephBamert (talk | contribs) im confusing my self someone needs to read over my work and make sure i didnt mess up something |

JosephBamert (talk | contribs) |

||

| (25 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

= Introduction to Vehicle Dynamics = | |||

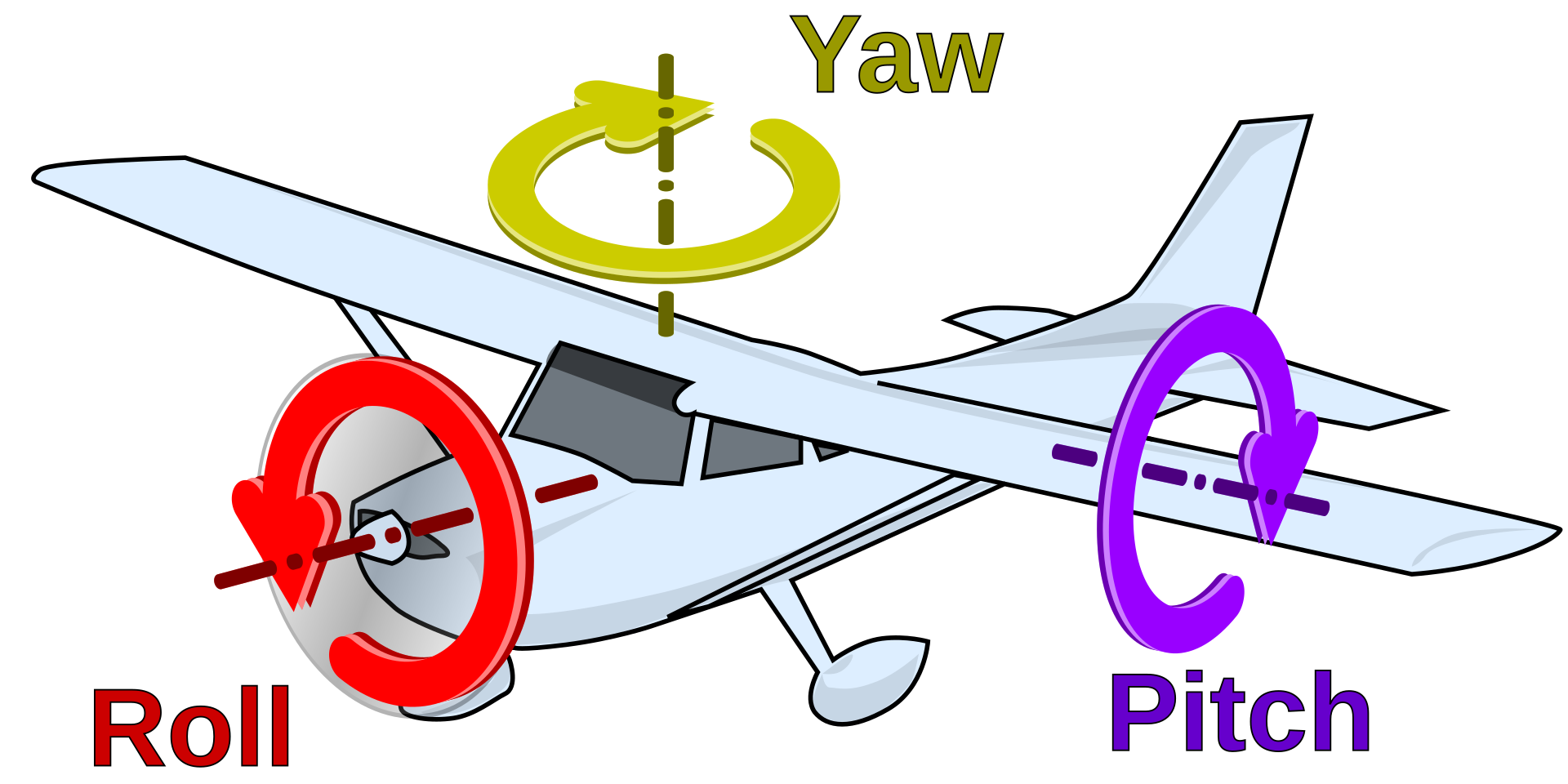

An FSAE car will experience | An FSAE car will experience six movement types: pitch, roll, yaw, heave, surge and sway. Pitch refers to the front vs back rotation of the car, for example if the car is pitched forward the front will be lower to the ground than the rear. Roll refers to the side vs side rotation of the car, for example a car with soft suspension turning right the body will noticeably lean to the left when looking at the vehicle face on. Yaw is the rotation of the vehicle around the yaw axis, for example a car losing traction on its rear wheels and starts to swing around is experiencing yaw. Heave is the vertical movement of the car. For example, when producing downforce, a car will "sink" into the ground. Surge and sway are not significantly considered in suspension <sup>(prove me wrong im not sure)</sup>. | ||

[[File:Flight dynamics with text.svg.png|thumb|273x273px]] | [[File:Flight dynamics with text.svg.png|thumb|273x273px]] | ||

Suspension controls the dynamics of these movements. This is done using dampers and a form of spring. A spring provides resistance and compliance for sprung mass of the car relative to the unsprung mass. A damper controls the oscillation of the spring. Unsprung mass is as it sounds; everything on the vehicle that is not supported by the spring. This includes: the tire, the wheel, the hub, the upright/knuckle assembly, as well as a portion of the spring assembly and control arms. Sprung mass is all of the mass on the vehicle that is supported (or sprung) by the spring. | Suspension controls the dynamics of these movements. This is done using dampers and a form of spring. A spring provides resistance and compliance for sprung mass of the car relative to the [[Unsprung Mass|unsprung mass]]. A damper controls the oscillation of the spring. Unsprung mass is as it sounds; everything on the vehicle that is not supported by the spring. This includes: the tire, the wheel, the hub, the upright/knuckle assembly, as well as a portion of the spring assembly and control arms. [[Sprung Mass|Sprung mass]] is all of the mass on the vehicle that is supported (or sprung) by the spring. | ||

== Our Goal == | |||

Our goal is to build and set up a suspension system that provides positive vehicle dynamics. Positive vehicle dynamics is a quite subjective term, but for us it largely making the car drive as fast as possible by maintaining large amounts of grip through the tires. Contrary to road vehicles, comfort is not a priority. Another complication is added as the suspension also must work with the aero of the car in order to provide downforce and less drag. For example, with the F25 it was discovered that stiffer springs improved the aerodynamic consistency of the vehicle, thus allowing it the maintain more downforce through pitch, roll, and yaw. | Our goal is to build and set up a suspension system that provides positive vehicle dynamics. Positive vehicle dynamics is a quite subjective term, but for us it largely making the car drive as fast as possible by maintaining large amounts of grip through the tires. Contrary to road vehicles, comfort is not a priority. Another complication is added as the suspension also must work with the aero of the car in order to provide downforce and less drag. For example, with the [[F25]] it was discovered that stiffer springs improved the aerodynamic consistency of the vehicle, thus allowing it the maintain more downforce through pitch, roll, and yaw. | ||

== Springs and Dampers == | |||

Every spring has a rate which determines the force needed to compress or extend it. This is the k-constant or spring constant. Changing a springs rate can change the amount of load, or force, a given tire receives at a given time. Because springs | Every [[spring]] has a rate which determines the force needed to compress or extend it. This is the k-constant or spring constant. Changing a springs rate can change the amount of load, or force, a given tire receives at a given time. Because springs oscillate and in a perfect system would oscillate forever, a [[damper]] is needed to control its osculation. | ||

A damper is a hydraulic device placed within the spring most often that will convert the kinetic energy of a force into another form, often heat. This is done by forcing a hydraulic fluid through small passageways, thus reducing the springs kinetic energy. It is important to note that '''dampers do not change tire load levels but rather control the speed at which the load changes'''. The dampers we use are 4-way adjustable. This mean we can adjust the rebound and compression (called bump by people who are wrong) dynamics of the damper separately as well as adjust the "fast" rebound and compression separately. Fast rebound and compression are described as a relatively (usually significantly) quicker compression or expansion of the damper. This most often occurs when attacking something like a racing kerb, where it is beneficial for the damper and spring to compress quickly to absorb the impact rather than send the car flying. Compression controls the kinetic energy the damper absorbs when being compressed. Rebound controls the kinetic energy the damper absorbs when being extended. The terminology concerning dampers is often extremely confusing and contradictory, so in this page we will be using the following terminology: '''Lowering the damping force means lowering the resistance the damper provides to the spring.''' This makes the spring and suspension move faster. | |||

A | |||

When a damper is completely compressed it hits what is called a [[Bump Stop|bump stop]]. A bump stop is a mechanism used to dissipate the kinetic energy of the damper over a longer period of time in order to eliminate a jarring "bump" and to prevent damage to the damper. Most often the bump stop is a small rubber piece that gets compressed when the dampers travel maxes out. | |||

== Basic Theory == | |||

A tire's grip level is determined through the friction coefficient between it and the ground, the force the tire is putting into the ground, and contact patch (the area of which the tire is in contact with the ground. A higher grip level allows the car to take corners faster. Suspension controls the dynamics of pitch, roll, and yaw which in hand controls the force each tire is putting into the ground at a moment. This force changes through a [[load transfer]] of the vehicle. Load transfer occurs because the center of mass of the vehicle is higher than the tires, thus it pushes a set of tires into the ground with a greater force than the other. Think of the center of mass of the vehicle as the point about which the car will rotate when a force, such as braking, is applied. With changes to the suspension, we can change the speed and extent of which a load transfer occurs. We want to design and tune our suspension in such a way that the car maintains high levels of grip while also promoting rotation through corner and driver control. | |||

==== In Roll | === In Pitch === | ||

Roll of a car occurs during a turn where the centripetal force will push the body of the car outwards. The dynamics of roll include a | Pitch of a car is caused by either acceleration or braking in a straight line. When braking, due to the vehicles center of mass being higher than the unsprung and driving mass, load shifts to the front tires. The total load being shifted to the front tires cannot be changed by the spring stiffness. Total longitudinal load being shifted is determined by the car's mass, wheelbase length, and center of gravity height. | ||

Suspension stiffness can be used to change the dynamics of braking. If a driver prefers a car with a oversteer bias when braking, a greater spring rate can be used for the rear wheels or a softer spring can be used for the fronts, thus increasing the fronts grip and decreasing the rear wheels grip and allowing the car to rotate upon entry to the corner. Changing suspension stiffness does not change the amount of load shifted but rather increases or decreases the grip of an axle through compliance allowing the tire's contact patch to increase or decrease. | |||

The damper forces can also be changed to influence pitch under braking. A lower compression damping force on the fronts will cause the front to pitch rapidly forward while a high compression damping force will cause the front to ease slowly into its pitch. Too low of a compression damping force on the fronts can cause oversteer as a rapid pitch forward and extreme change in load transfer to the front causes a sudden loss of rear grip. Too high of a compression damping force on the front can cause understeer as the front becomes "lazy" and load does not transfer to the front quickly enough to provide the grip needed to the front tires thus causing understeer. Lowering the rear rebound force can also reduce oversteer as it allows the rear tires to quickly move to be in constant contact with the ground as the car's load shifts forward, thus providing more consistent rear grip. | |||

When accelerating, since the vehicle's center of mass is higher than the unsprung and driving mass, the load shifts toward the rear tires. In most cases this is inherently beneficial as the rear wheels drive a FSAE car and more force leads to more grip which leads to better acceleration. When accelerating out of a corner, the front dampers are rebounding, and the rears are compressing. In extreme cases, lack of traction and therefore oversteer can be caused by too low of a rear compression damping force as the initial load shift may cause the rear spring to oscillate and thus skate the rear tires across the surface. Understeer can be caused under acceleration by too low of a rear compression damping force, as a quick pitch rearward will cause the front wheels to become unloaded too quickly and lose grip. | |||

=== In Roll === | |||

Roll of a car occurs during a turn where the centripetal force will push the body of the car outwards. The dynamics of roll include a load transfer to the outside wheels and the inside wheels traveling less distance in a circle. This load transfer to the outside wheel is known as lateral load transfer. The vehicle's total lateral load transfer cannot be changed through suspension tuning as it is solely determined by [[trackwidth]], total mass, and the height of the vehicle's center of mass. A greater lateral load transfer is generally bad as due to [[Tire#Load sensitivity|load sensitivity]], a tire's grip does not increase proportionally to the amount of load the tire has. | |||

While the total lateral load transfer cannot be changed, the distribution of this load through the front and rear axles can be changed. Changing the height of the axle's [[Front View Swing Arm|roll center]] or the axle's [[roll stiffness]] will change how much of the total lateral load will be sent through that axle. Increasing the amount of the total lateral load an axle bears will decrease the amount of the total lateral load the other axle bears. | |||

Increasing the lateral load on the rear axle will lead towards an oversteer bias. Increasing the lateral load on the front axle will lead towards an understeer bias. Because the axle's loads are directly related as they must sum up to the vehicles total lateral load, a decrease in the front axle's lateral load will also move the car towards an oversteer bias. | |||

There are two ways to control a vehicle's roll stiffness: spring rates and anti-roll bars. Increasing an axle's spring rates will increase that axle's roll stiffness and thus increase the amount of total lateral load it bears. Keep in mind modifying spring rates has effects on other car dynamics. Roll stiffness can be controlled independently through the use of an anti-roll bar. An anti-roll bar resists roll, therefore increasing roll stiffness most often by twisting a rod. As of 2025, we do not use a roll bar due to packaging and weight. | |||

=== Accounting for Aero === | |||

In general, the more a fluctuation aero package has when driving, the less consistently downforce will be produced. Because suspension basically controls the fluctuation and location of the whole cars mass, the suspensions effect on aero needs to be considered. Generally, the stiffer the car is, the more consistent the downforce is produced. Additionally, when the car is lower to the ground, more downforce is produced (until aero stall) (think 2022 F1). Driving the car with stiffer suspension allows it to be closer to the ground as the cars body will not bounce as much into the ground. Recently (2025), [[Aero]] has become responsible for setting the ride height. | |||

==== Heave ==== | |||

Heave is the vertical motion of the vehicle. Under aero load, a FSAE car experiences heave as downforce pushes the car into the ground. Suspension must ensure the car will have significant suspension travel left under heave at high downforce. Heave can be controlled independently through the use of a [[heave spring]]. A heave spring only is compressed when both springs on an axle are compressed. [[File:Annotation 2025-07-24 094249.png|thumb|282x282px|slip angle demonstration]] | |||

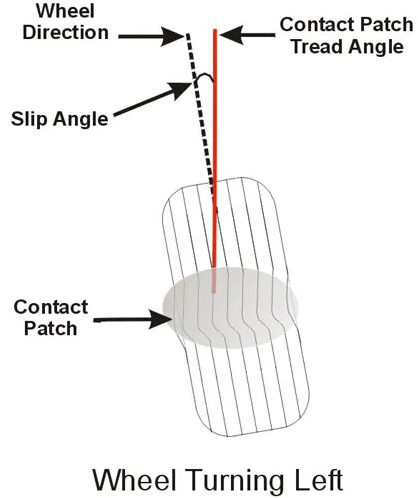

=== Slip-Angle === | |||

[[Slip angle]] is the angle between the direction a [[tire]] is pointing and the direction it is traveling. Slip angle results in a force perpendicular to the direction the tire is pointing called cornering force. Slip angle causes a deformation in the tire tread, which in turn acts as a spring causing cornering force. The cornering force is proportional to slip angle until a point at which it increases non-linearly and then decreases. | |||

The ratio of slip angles for the front to rear tires determines the car's behavior in a turn. A ratio greater than 1:1 demonstrates understeer while a ratio less than 1:1 demonstrates oversteer. This ratio can be changed by modifying a car's roll center, spring rates, or anti roll bars relative front to rear. | |||

= Geometry = | |||

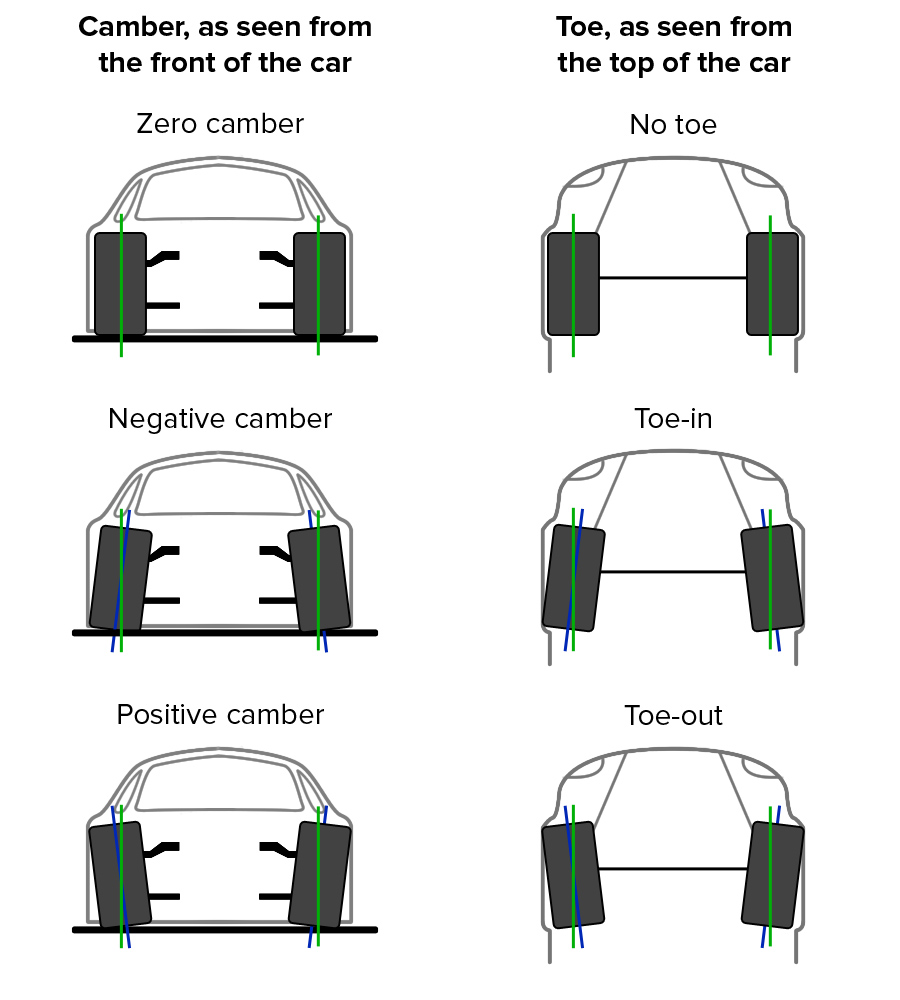

The unsprung mass of the vehicle is just as important as the sprung. The alignment of the car largely determines the contact patch each tire has. There are three parts to alignment: toe, caster, and camber. The way a car steers its wheels can also affects its dynamics through Ackerman. | |||

== Toe == | |||

[[File:Toe-in.jpg|thumb]] | |||

Toe is the angle that each tire makes with the symmetrical horizontal axis of the vehicle. Toe-in or positive toe looks as if the wheels are pointed inwards. Toe-out or negative toe looks as if the wheels are pointed outward. Front toe-out provides a more aggressive turn in at the cost of lesser straight-line stability. The more positive the rear toe, the more slip angle the loaded outside [[tire]] will enter the corner with. This will shift the car towards an understeer bias. | |||

== Camber == | |||

Camber is the angle made by the vertical axis of the wheel face and the vertical symmetrical axis of the vehicle. Negative camber has the appearance of the bottom of the wheels pointing outwards when viewed from the front of the car. Every single wheel always should have negative camber. This is because while cornering, centripetal force will cause the car to lean on its outside wheels, and a degree of camber will increase the contact patch as the wheel will be parallel with the ground. This way the forces on the tire are perpendicular rather than shear. FSAE cars typically run between 1-3 degrees of negative camber. | |||

=== Camber Gain === | |||

Camber gain is how much the camber angle changes per vertical distance the suspension moves. When the wheel moves upwards relative to the sprung mass, the camber becomes more negative. Camber gain can be used to maximize tire's contact patch throughout a lap. | |||

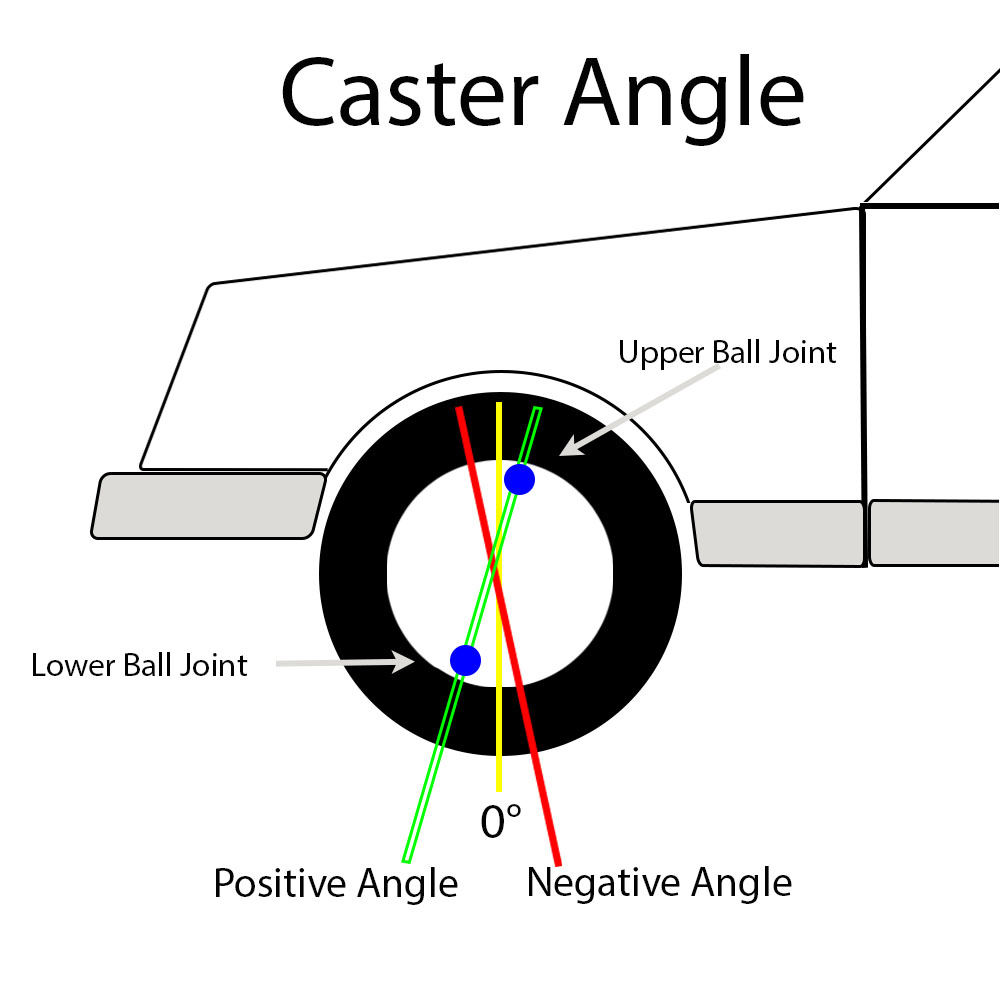

[[File:Caster diagram.jpg|thumb]] | |||

== Caster == | |||

Caster is the angle the steering axis makes with the vertical line at the center of the tire. Caster allows the front wheels to naturally align with the direction of travel. A larger caster angle in magnitude will cause the front wheels to self-center more aggressively. The larger a caster angle, the heaver the steering will feel. Large caster angles can be used to improve camber gain in corners. | |||

== Ackerman == | |||

Pro-Ackerman steering is steering where the inside tire turns in at a greater angle than the outside. Reverse-Ackerman steering is steering where the inside tire turns in at a greater angle than the outside. | |||

== Tire Pressure == | |||

The wrong tire pressure can cause an uneven distribution of force into the ground. Too low of a tire pressure can cause a lack of force in the middle of the tire's contact patch as well as lateral movement in the sidewall. Too great of a tire pressure can cause a lack of force on the sides of the tire's contact patch. | |||

== "Anti"-Geometry == | |||

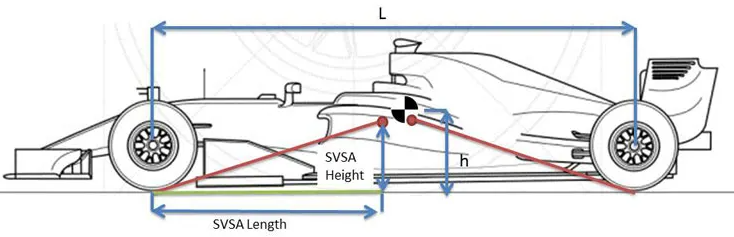

[[File:Antidiveex.png|thumb|422x422px|The red lines are SVSAs. The red dots are instant centers which are found by drawing a line from each control arm's 2 mounting points until they meet. ]] | |||

Wheel loading remains the same regardless of [[Anti-Geometry|anti-geometry]] because the total longitudinal load transfer under acceleration or braking is a function of wheelbase, forces and center of gravity height. Anti-geometry changes amount of load going through the springs and the pitch of the car. Thus, it is largely used for aero benefits. | |||

=== Side View Swing Arms (SVSA) === | |||

[[Anti-Geometry#Side View Swing Arms|SVSA]] is a line from an instant center to its respective tire's contact patch and is used to calculate the percent of anti-dive or anti-squat a suspension has. | |||

=== Anti-Dive === | |||

Dive occurs under braking and is the motion of the car pitching forward. Anti-dive restricts the front suspension's compression when under braking. Anti-dive percentage can be changed by modifying the geometry of the front control arms. | |||

=== Anti-Squat === | |||

Squat occurs under acceleration and is the motion of the car squatting rearwards. Anti-squat restricts the rear suspension's compression when under acceleration. Anti-squat percentage can be changed by modifying the geometry of the rear control arms. | |||

== Front View Swing Arm (FVSA) == | |||

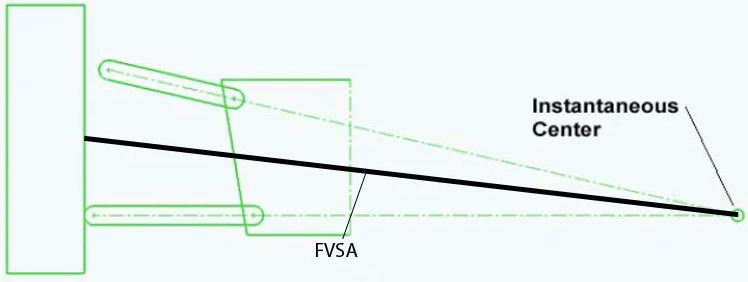

[[File:Annotation 2025-07-15 103433.png|thumb|FVSA example]] | |||

The [[Front View Swing Arm|FVSA]] is theoretical line from the center of the upright that pivots around the FVSA instant center. The FVSA instant center is determined by the meeting point of the where lines drawn from the upper and lower control arms meet. The FVSA instant center determines the vehicle's roll center, lateral scrub rate, and camber gain. The longer the FSVA, the less camber gain the suspension has. | |||

= Design Methods = | |||

== CAD == | |||

Ensure full subsystem integration to avoid problems when manufacturing. | |||

= Manufacturing Methods = | |||

== Lathe == | |||

The coolest one. great for making circular symmetric parts. | |||

== Outsourcing == | |||

Alum-A-Lift | |||

== Manual Milling == | |||

== CNC Milling == | |||

Haas | |||

= General Advice = | |||

* '''Keeping editing and adding to the wiki.''' The key to long term success is knowledge transfer. | |||

== Drive Days == | |||

* Bolt check before you leave | |||

* Visually inspect each bolt - don't just shake | |||

* make sure wheel nuts are torqued | |||

* Inspect bearings as well as bolts | |||

== Competitions == | |||

* Bring the car | |||

* Pack scales | |||

= Suspension History and Lessons Learned = | |||

== 2024-2025 F25 == | |||

=== Leadership === | |||

James Millington and Tomek (rip) | |||

=== Highlights === | |||

* Change to KW Dampers from Ohlins | |||

** Lighter, indexed adjustments, and the Ohlins leaked (note: this last one alone is not valid reasoning) | |||

* Right front hub failure | |||

** FEA conducted on model without threads, and no stress concentration factor was applied to von mises stress result. No proper fatigue analysis conducted, either. | |||

* 330+ test miles | |||

* 1st endurance, 2nd autocross, 3rd overall at Michigan | |||

=== Lessons === | |||

==== Aero Integration ==== | |||

This year had better integration between aero and suspension, leading to the car running much stiffer to prevent roll outside the aerodynamic operating range. Aero also became responsible for setting ride height. | |||

==== Testing is VERY Important ==== | |||

Compared to F24, F25 got significantly more testing which helped with driver development as well as general setup and preparedness. | |||

==== F25 Upright Camber Plate Design Sucked ==== | |||

Bolts did not fit properly so the camber operating window was very small. It also takes a long time to change out the plates. | |||

==== Hubs ==== | |||

Hub bubs | |||

== 2025-2026 F26 == | |||

=== Leadership === | |||

Emmet Norrell and Johnny Lu | |||

=== Highlights === | |||

* reintroduction of front and rear suspension rockers | |||

=== Lessons === | |||

==== Emphasize Knowledge Transfer ==== | |||

With James becoming Chief, Tomek going to Williams, and Zac graduating a large gap was left in our knowledge of vehicle dynamics and vehicle simulation. This wiki is part of our effort to fix our wrong doings and ensure future team success. | |||

Latest revision as of 18:02, 29 October 2025

Introduction to Vehicle Dynamics[edit | edit source]

An FSAE car will experience six movement types: pitch, roll, yaw, heave, surge and sway. Pitch refers to the front vs back rotation of the car, for example if the car is pitched forward the front will be lower to the ground than the rear. Roll refers to the side vs side rotation of the car, for example a car with soft suspension turning right the body will noticeably lean to the left when looking at the vehicle face on. Yaw is the rotation of the vehicle around the yaw axis, for example a car losing traction on its rear wheels and starts to swing around is experiencing yaw. Heave is the vertical movement of the car. For example, when producing downforce, a car will "sink" into the ground. Surge and sway are not significantly considered in suspension (prove me wrong im not sure).

Suspension controls the dynamics of these movements. This is done using dampers and a form of spring. A spring provides resistance and compliance for sprung mass of the car relative to the unsprung mass. A damper controls the oscillation of the spring. Unsprung mass is as it sounds; everything on the vehicle that is not supported by the spring. This includes: the tire, the wheel, the hub, the upright/knuckle assembly, as well as a portion of the spring assembly and control arms. Sprung mass is all of the mass on the vehicle that is supported (or sprung) by the spring.

Our Goal[edit | edit source]

Our goal is to build and set up a suspension system that provides positive vehicle dynamics. Positive vehicle dynamics is a quite subjective term, but for us it largely making the car drive as fast as possible by maintaining large amounts of grip through the tires. Contrary to road vehicles, comfort is not a priority. Another complication is added as the suspension also must work with the aero of the car in order to provide downforce and less drag. For example, with the F25 it was discovered that stiffer springs improved the aerodynamic consistency of the vehicle, thus allowing it the maintain more downforce through pitch, roll, and yaw.

Springs and Dampers[edit | edit source]

Every spring has a rate which determines the force needed to compress or extend it. This is the k-constant or spring constant. Changing a springs rate can change the amount of load, or force, a given tire receives at a given time. Because springs oscillate and in a perfect system would oscillate forever, a damper is needed to control its osculation.

A damper is a hydraulic device placed within the spring most often that will convert the kinetic energy of a force into another form, often heat. This is done by forcing a hydraulic fluid through small passageways, thus reducing the springs kinetic energy. It is important to note that dampers do not change tire load levels but rather control the speed at which the load changes. The dampers we use are 4-way adjustable. This mean we can adjust the rebound and compression (called bump by people who are wrong) dynamics of the damper separately as well as adjust the "fast" rebound and compression separately. Fast rebound and compression are described as a relatively (usually significantly) quicker compression or expansion of the damper. This most often occurs when attacking something like a racing kerb, where it is beneficial for the damper and spring to compress quickly to absorb the impact rather than send the car flying. Compression controls the kinetic energy the damper absorbs when being compressed. Rebound controls the kinetic energy the damper absorbs when being extended. The terminology concerning dampers is often extremely confusing and contradictory, so in this page we will be using the following terminology: Lowering the damping force means lowering the resistance the damper provides to the spring. This makes the spring and suspension move faster.

When a damper is completely compressed it hits what is called a bump stop. A bump stop is a mechanism used to dissipate the kinetic energy of the damper over a longer period of time in order to eliminate a jarring "bump" and to prevent damage to the damper. Most often the bump stop is a small rubber piece that gets compressed when the dampers travel maxes out.

Basic Theory[edit | edit source]

A tire's grip level is determined through the friction coefficient between it and the ground, the force the tire is putting into the ground, and contact patch (the area of which the tire is in contact with the ground. A higher grip level allows the car to take corners faster. Suspension controls the dynamics of pitch, roll, and yaw which in hand controls the force each tire is putting into the ground at a moment. This force changes through a load transfer of the vehicle. Load transfer occurs because the center of mass of the vehicle is higher than the tires, thus it pushes a set of tires into the ground with a greater force than the other. Think of the center of mass of the vehicle as the point about which the car will rotate when a force, such as braking, is applied. With changes to the suspension, we can change the speed and extent of which a load transfer occurs. We want to design and tune our suspension in such a way that the car maintains high levels of grip while also promoting rotation through corner and driver control.

In Pitch[edit | edit source]

Pitch of a car is caused by either acceleration or braking in a straight line. When braking, due to the vehicles center of mass being higher than the unsprung and driving mass, load shifts to the front tires. The total load being shifted to the front tires cannot be changed by the spring stiffness. Total longitudinal load being shifted is determined by the car's mass, wheelbase length, and center of gravity height.

Suspension stiffness can be used to change the dynamics of braking. If a driver prefers a car with a oversteer bias when braking, a greater spring rate can be used for the rear wheels or a softer spring can be used for the fronts, thus increasing the fronts grip and decreasing the rear wheels grip and allowing the car to rotate upon entry to the corner. Changing suspension stiffness does not change the amount of load shifted but rather increases or decreases the grip of an axle through compliance allowing the tire's contact patch to increase or decrease.

The damper forces can also be changed to influence pitch under braking. A lower compression damping force on the fronts will cause the front to pitch rapidly forward while a high compression damping force will cause the front to ease slowly into its pitch. Too low of a compression damping force on the fronts can cause oversteer as a rapid pitch forward and extreme change in load transfer to the front causes a sudden loss of rear grip. Too high of a compression damping force on the front can cause understeer as the front becomes "lazy" and load does not transfer to the front quickly enough to provide the grip needed to the front tires thus causing understeer. Lowering the rear rebound force can also reduce oversteer as it allows the rear tires to quickly move to be in constant contact with the ground as the car's load shifts forward, thus providing more consistent rear grip.

When accelerating, since the vehicle's center of mass is higher than the unsprung and driving mass, the load shifts toward the rear tires. In most cases this is inherently beneficial as the rear wheels drive a FSAE car and more force leads to more grip which leads to better acceleration. When accelerating out of a corner, the front dampers are rebounding, and the rears are compressing. In extreme cases, lack of traction and therefore oversteer can be caused by too low of a rear compression damping force as the initial load shift may cause the rear spring to oscillate and thus skate the rear tires across the surface. Understeer can be caused under acceleration by too low of a rear compression damping force, as a quick pitch rearward will cause the front wheels to become unloaded too quickly and lose grip.

In Roll[edit | edit source]

Roll of a car occurs during a turn where the centripetal force will push the body of the car outwards. The dynamics of roll include a load transfer to the outside wheels and the inside wheels traveling less distance in a circle. This load transfer to the outside wheel is known as lateral load transfer. The vehicle's total lateral load transfer cannot be changed through suspension tuning as it is solely determined by trackwidth, total mass, and the height of the vehicle's center of mass. A greater lateral load transfer is generally bad as due to load sensitivity, a tire's grip does not increase proportionally to the amount of load the tire has.

While the total lateral load transfer cannot be changed, the distribution of this load through the front and rear axles can be changed. Changing the height of the axle's roll center or the axle's roll stiffness will change how much of the total lateral load will be sent through that axle. Increasing the amount of the total lateral load an axle bears will decrease the amount of the total lateral load the other axle bears.

Increasing the lateral load on the rear axle will lead towards an oversteer bias. Increasing the lateral load on the front axle will lead towards an understeer bias. Because the axle's loads are directly related as they must sum up to the vehicles total lateral load, a decrease in the front axle's lateral load will also move the car towards an oversteer bias.

There are two ways to control a vehicle's roll stiffness: spring rates and anti-roll bars. Increasing an axle's spring rates will increase that axle's roll stiffness and thus increase the amount of total lateral load it bears. Keep in mind modifying spring rates has effects on other car dynamics. Roll stiffness can be controlled independently through the use of an anti-roll bar. An anti-roll bar resists roll, therefore increasing roll stiffness most often by twisting a rod. As of 2025, we do not use a roll bar due to packaging and weight.

Accounting for Aero[edit | edit source]

In general, the more a fluctuation aero package has when driving, the less consistently downforce will be produced. Because suspension basically controls the fluctuation and location of the whole cars mass, the suspensions effect on aero needs to be considered. Generally, the stiffer the car is, the more consistent the downforce is produced. Additionally, when the car is lower to the ground, more downforce is produced (until aero stall) (think 2022 F1). Driving the car with stiffer suspension allows it to be closer to the ground as the cars body will not bounce as much into the ground. Recently (2025), Aero has become responsible for setting the ride height.

Heave[edit | edit source]

Heave is the vertical motion of the vehicle. Under aero load, a FSAE car experiences heave as downforce pushes the car into the ground. Suspension must ensure the car will have significant suspension travel left under heave at high downforce. Heave can be controlled independently through the use of a heave spring. A heave spring only is compressed when both springs on an axle are compressed.

Slip-Angle[edit | edit source]

Slip angle is the angle between the direction a tire is pointing and the direction it is traveling. Slip angle results in a force perpendicular to the direction the tire is pointing called cornering force. Slip angle causes a deformation in the tire tread, which in turn acts as a spring causing cornering force. The cornering force is proportional to slip angle until a point at which it increases non-linearly and then decreases.

The ratio of slip angles for the front to rear tires determines the car's behavior in a turn. A ratio greater than 1:1 demonstrates understeer while a ratio less than 1:1 demonstrates oversteer. This ratio can be changed by modifying a car's roll center, spring rates, or anti roll bars relative front to rear.

Geometry[edit | edit source]

The unsprung mass of the vehicle is just as important as the sprung. The alignment of the car largely determines the contact patch each tire has. There are three parts to alignment: toe, caster, and camber. The way a car steers its wheels can also affects its dynamics through Ackerman.

Toe[edit | edit source]

Toe is the angle that each tire makes with the symmetrical horizontal axis of the vehicle. Toe-in or positive toe looks as if the wheels are pointed inwards. Toe-out or negative toe looks as if the wheels are pointed outward. Front toe-out provides a more aggressive turn in at the cost of lesser straight-line stability. The more positive the rear toe, the more slip angle the loaded outside tire will enter the corner with. This will shift the car towards an understeer bias.

Camber[edit | edit source]

Camber is the angle made by the vertical axis of the wheel face and the vertical symmetrical axis of the vehicle. Negative camber has the appearance of the bottom of the wheels pointing outwards when viewed from the front of the car. Every single wheel always should have negative camber. This is because while cornering, centripetal force will cause the car to lean on its outside wheels, and a degree of camber will increase the contact patch as the wheel will be parallel with the ground. This way the forces on the tire are perpendicular rather than shear. FSAE cars typically run between 1-3 degrees of negative camber.

Camber Gain[edit | edit source]

Camber gain is how much the camber angle changes per vertical distance the suspension moves. When the wheel moves upwards relative to the sprung mass, the camber becomes more negative. Camber gain can be used to maximize tire's contact patch throughout a lap.

Caster[edit | edit source]

Caster is the angle the steering axis makes with the vertical line at the center of the tire. Caster allows the front wheels to naturally align with the direction of travel. A larger caster angle in magnitude will cause the front wheels to self-center more aggressively. The larger a caster angle, the heaver the steering will feel. Large caster angles can be used to improve camber gain in corners.

Ackerman[edit | edit source]

Pro-Ackerman steering is steering where the inside tire turns in at a greater angle than the outside. Reverse-Ackerman steering is steering where the inside tire turns in at a greater angle than the outside.

Tire Pressure[edit | edit source]

The wrong tire pressure can cause an uneven distribution of force into the ground. Too low of a tire pressure can cause a lack of force in the middle of the tire's contact patch as well as lateral movement in the sidewall. Too great of a tire pressure can cause a lack of force on the sides of the tire's contact patch.

"Anti"-Geometry[edit | edit source]

Wheel loading remains the same regardless of anti-geometry because the total longitudinal load transfer under acceleration or braking is a function of wheelbase, forces and center of gravity height. Anti-geometry changes amount of load going through the springs and the pitch of the car. Thus, it is largely used for aero benefits.

Side View Swing Arms (SVSA)[edit | edit source]

SVSA is a line from an instant center to its respective tire's contact patch and is used to calculate the percent of anti-dive or anti-squat a suspension has.

Anti-Dive[edit | edit source]

Dive occurs under braking and is the motion of the car pitching forward. Anti-dive restricts the front suspension's compression when under braking. Anti-dive percentage can be changed by modifying the geometry of the front control arms.

Anti-Squat[edit | edit source]

Squat occurs under acceleration and is the motion of the car squatting rearwards. Anti-squat restricts the rear suspension's compression when under acceleration. Anti-squat percentage can be changed by modifying the geometry of the rear control arms.

Front View Swing Arm (FVSA)[edit | edit source]

The FVSA is theoretical line from the center of the upright that pivots around the FVSA instant center. The FVSA instant center is determined by the meeting point of the where lines drawn from the upper and lower control arms meet. The FVSA instant center determines the vehicle's roll center, lateral scrub rate, and camber gain. The longer the FSVA, the less camber gain the suspension has.

Design Methods[edit | edit source]

CAD[edit | edit source]

Ensure full subsystem integration to avoid problems when manufacturing.

Manufacturing Methods[edit | edit source]

Lathe[edit | edit source]

The coolest one. great for making circular symmetric parts.

Outsourcing[edit | edit source]

Alum-A-Lift

Manual Milling[edit | edit source]

CNC Milling[edit | edit source]

Haas

General Advice[edit | edit source]

- Keeping editing and adding to the wiki. The key to long term success is knowledge transfer.

Drive Days[edit | edit source]

- Bolt check before you leave

- Visually inspect each bolt - don't just shake

- make sure wheel nuts are torqued

- Inspect bearings as well as bolts

Competitions[edit | edit source]

- Bring the car

- Pack scales

Suspension History and Lessons Learned[edit | edit source]

2024-2025 F25[edit | edit source]

Leadership[edit | edit source]

James Millington and Tomek (rip)

Highlights[edit | edit source]

- Change to KW Dampers from Ohlins

- Lighter, indexed adjustments, and the Ohlins leaked (note: this last one alone is not valid reasoning)

- Right front hub failure

- FEA conducted on model without threads, and no stress concentration factor was applied to von mises stress result. No proper fatigue analysis conducted, either.

- 330+ test miles

- 1st endurance, 2nd autocross, 3rd overall at Michigan

Lessons[edit | edit source]

Aero Integration[edit | edit source]

This year had better integration between aero and suspension, leading to the car running much stiffer to prevent roll outside the aerodynamic operating range. Aero also became responsible for setting ride height.

Testing is VERY Important[edit | edit source]

Compared to F24, F25 got significantly more testing which helped with driver development as well as general setup and preparedness.

F25 Upright Camber Plate Design Sucked[edit | edit source]

Bolts did not fit properly so the camber operating window was very small. It also takes a long time to change out the plates.

Hubs[edit | edit source]

Hub bubs

2025-2026 F26[edit | edit source]

Leadership[edit | edit source]

Emmet Norrell and Johnny Lu

Highlights[edit | edit source]

- reintroduction of front and rear suspension rockers

Lessons[edit | edit source]

Emphasize Knowledge Transfer[edit | edit source]

With James becoming Chief, Tomek going to Williams, and Zac graduating a large gap was left in our knowledge of vehicle dynamics and vehicle simulation. This wiki is part of our effort to fix our wrong doings and ensure future team success.