Tire

A tire refers to the ring of rubber around the wheel (or rim) that is in contact with the ground. Tires are the only link between a FSAE car in the ground and thus are extremely important (duh). For a tire alignment overview, check out suspension handbook geometry page.

Characteristics[edit | edit source]

Balance[edit | edit source]

In order to rotate smoothly a tire must have an even distribution of mass around its circumference. An unbalanced tire will vibrate. This can be corrected by applying weights on the wheel to balance it.

Centrifugal expansion[edit | edit source]

When a tire turns at a high rate of speed, it has centrifugal force. If a tire spins fast enough, the centrifugal force generated may be enough to increase the diameter of the tire through "pulling" on the rubber sidewalls. This is not a notable issue on FSAE cars.

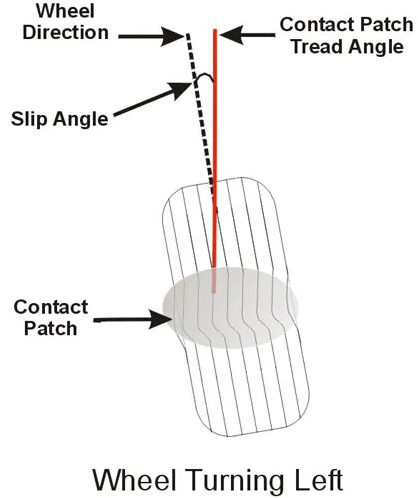

Slip angle[edit | edit source]

Slip angle is the angle between the direction a tire is pointing and the direction it is traveling. Slip angle results in a force perpendicular to the direction the tire is pointing called cornering force. Slip angle causes a deformation in the tire tread, which in turn acts as a spring. This "spring" has a returning force which is the cornering force. At low angles of slip, corner force increases linearly with slip angle. As the angle of slip increases, it will eventually reach a point at which the corner force increases non-linearly with slip angle. Finally, the tire will reach a peak cornering force and thereon after an increase in slip angle will decrease cornering force.

The ratio of slip angles for the front to rear tires determines the car's behavior in a turn. A ratio greater than 1:1 demonstrates understeer while a ratio less than 1:1 demonstrates oversteer. This ratio can be changed by modifying a car's roll center, spring rates, or anti roll bars relative front to rear.

Circle of Forces[edit | edit source]

Circle of forces is a way in which to visualize the forces acting between a tire and the road. It is a 2D visualization viewing the tire from the top, with the tire rolling on the xy-plane which acts as the ground. The y-axis is the direction of travel of the vehicle of which the tire is attached. The diameter of the circle is the maximum magnitude of lateral force the tire can generate. The diameter of the circle depends on the road surface, load, and condition of the tire, so basically the amount of friction available. In real life, the circle is usually an ellipse with the y direction being longer than the x.

In this example the tire is turned to the right. The tire is pointed in a different direction than the direction of travel and thus must slip. It generates a horizontal force (F) by the mechanism of slip. F is perpendicular to the wheel direction. The X component of the force is transferred through the suspension to the chassis thus causing the vehicle to turn right.

Relaxation length[edit | edit source]

Relaxation length describes the delay between a slip angle occurring and the time it takes for the corner force to reach a steady state. It can be calculated as cornering stiffness over lateral stiffness. Cornering stiffness is the ratio of cornering force over slip angle. Lateral stiffness is the ratio of lateral force over lateral displacement.

Spring rate[edit | edit source]

Yep. Tires are also springs. The spring rate of a tire is the k-constant of its vertical stiffness. The magnitude of the k-constant determines the tire vertical deflection under load. This is largely influenced by the sidewall stiffness and air pressure.

Contact Patch[edit | edit source]

A tire's contact patch is the area in which it is in contact with the ground. The contact patch of a tire is constantly changing due to different loads being put through the tire. The length to width ratio of the patch affects cornering behavior.

Force Variation[edit | edit source]

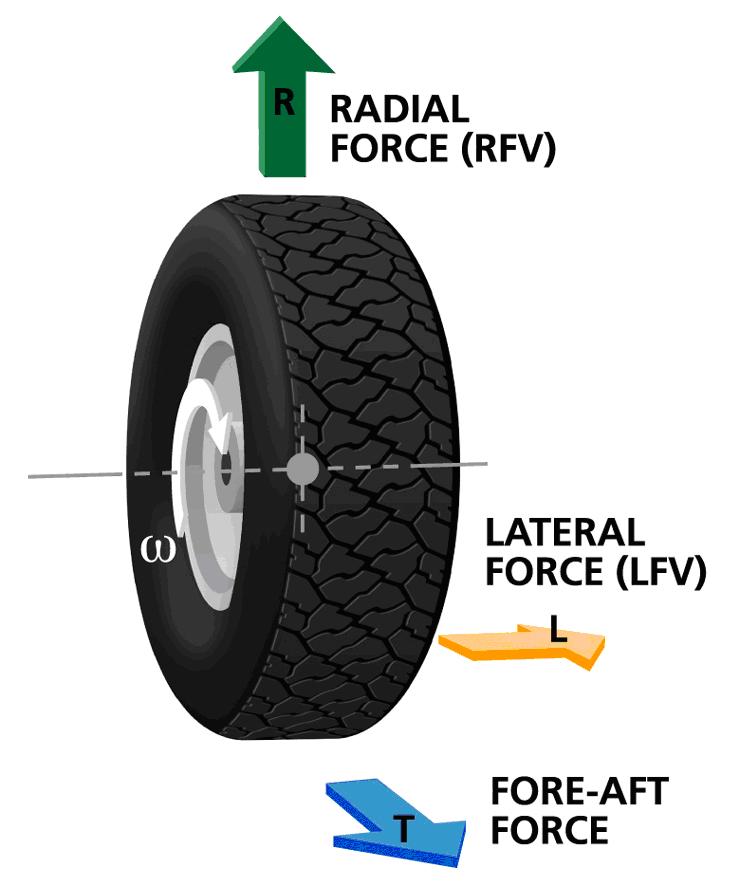

Lateral Force Variation[edit | edit source]

Lateral Force Variation describes the dynamic behavior of the lateral force of the tire. As a tire rolls it deforms as it enters and exits the contact patch. A typical tire's lateral force between the tire and the wheel varies as it turns. For example, a tire with a good LFV of 2 pounds will exert 2 pounds of force laterally into the vehicle every rotation. It can influence the steering of the vehicle. Tire manufactures test their tires to ensure they are within set LFV limits.

Radial Force Variation[edit | edit source]

Radial Force Variation describes the dynamic behavior of the radial force of the tire. As a tire rolls it deforms as it enters and exits the contact patch. A typical tire's radial force between the tire and the wheel varies as it turns. The variation is product of the inconsistent thickness and elastic properties of a tire. For example, a tire with a good TFV of 5 pounds will exert 5 pounds of force vertically into the vehicle every rotation. Tire manufactures test their tires to ensure they are within set RFV limits.

Tangential Force Variation[edit | edit source]

Tangential Force Variation describes the dynamic behavior of the tangential/fore-aft force of the tire. As a tire rolls it deforms as it enters and exits the contact patch. A typical tire's tangential force between the tire and the wheel varies as it turns. The variation is product of the inconsistent thickness and elastic properties of a tire. For example, a tangential force variation manifests itself as an itty-bitty fluctuation in speed every tire rotation as the tire's radius changes. Tire manufactures test their tires to ensure they are within set TFV limits.

Rolling Resistance[edit | edit source]

Rolling resistance is the transmission of energy into deforming the tire rather than being conserved. A rubber tire will deform as it rolls to match the road surface. This deformation however requires energy, which thus provides the resistance of the roll.

Load sensitivity[edit | edit source]

The load sensitivity of a tire is the way it behaves under load. Classical friction theory suggests the max horizontal force should be proportional to the tire's vertical load. This is not the case rather the max horizontal force that can be generated is proportional to the vertical load raised to a power often between 0.7 and 0.9. Basically, the maximum lateral force (traction or grip) that can be developed does increase as the vertical load increases, but at a diminishing rate.

Wear[edit | edit source]

Because the tire is experiencing friction as it rolls, it wears. This leads into the different types of extreme wear FSAE tires can experience. Optimum tire wear is show by a consistent slight ripple effect across most of the surface.

Graining[edit | edit source]

Graining occurs when the rubber of a tire spreads or separates and then fuses back together with the heat generated by the tire. It creates an uneven surface and can damage the physical characteristics of the rubber. Graining is caused by excess friction and heat. It most often occurs during excess over or under steer when which the tire gets dragged in a direction without pointing that way thus causing shear on the rubber, tearing it up and creating heat.

How do I stop it[edit | edit source]

Check where the graining is located on the tire. If it is concentrated to one side laterally, this indicates uneven wear. If the graining is concentrated on the outside of the tire, increase the magnitude of camber. If graining is concentrated on the inside of the tire, decrease your camber. Keep camber gain in mind. If the graining pattern is not consistent around the circumference, this indicates the tire is not in consistent contact with the ground and may be hopping. To fix this adjust your dampers, likely your rebound force is too stiff.

Look at graining tread pattern. If the front of the graining treads is raised, your rebound may be too slow (too stiff). If the rear of the graining treads is raised, your rebound may be too fast (too soft).

Too low or little tire pressure can be another culprit of graining. Check your tire pressure when the tire is hot off the track and make sure it is in its acceptable range. If graining is concentrated in the middle of the tire, it may indicate your tire pressures are too high. Equal graining along both edges may indicate your tire pressures are too low. Using nitrogen will help setting pressures as it does not expand under heat as significantly as atmospheric air.

If graining is consistent around the whole tire, the good news is that your alignment and dampers are not causing the issue. The bad news is it is a skill issue. The driver may be pushing the tire too hard while it is cold, causing shearing and overheating the surface. The driver could also just be pushing the tire too hard in general and overheating it. To mitigate this, you can tell him to chill a bit, or you can soften your spring rates to reduce the load through the tire.

Blistering[edit | edit source]

Blistering is when strips or chunks of rubber are detaching from the tire. Blistering occurs when the tire is extremely overheated. This heat causes the bonds holding the layers of rubber together to fail, thus causing detachment of large pieces.

How do I stop it[edit | edit source]

First, check your geometry and tire pressures, just like with graining.

Blistering is caused by overheating, and thus the best way to stop it is to eliminate excessive oversteer and understeer. This can be done by telling off the driver or softening the spring rates. If compression damping is too stiff (slow) it can cause the tire to act as spring before the actual suspension does. This will increase the heat of the tire as it is absorbing energy through its compression rather than the suspension. Too fast (soft) of compression damping can cause the tire to be loaded too quickly, overheating the tire.

As a close to last ditch effort, change your tire compound as the current one could be too soft for the conditions and is thus overheating. You should have finished the car earlier to test more if this is the case.

Flat Spot[edit | edit source]

A flat spot occurs when a tire's brake torque force exceeds the tire's static ground contact (friction) torque force thus leading to the tire to stop spinning (static friction becomes kinetic friction) while the car is still moving, thus slicing rubber off the contact patch. This is called a brake lock up. A less significant flat spot can occur if a hot tire cools down stationary, thus forming a small pushed in or flat spot where it meets the ground. This will usually go away after the tire heats up again.

How do I stop it[edit | edit source]

ABS can be used to reduce or eliminate the locking of a tire. When the ABS speed sensors sense a tire locking, it will pulse the brakes to reduce a lock up and thus a flat spot. As of 2025, we do not implement ABS because it is heavy, complex, and kind of a skill issue if you need it.

The best way to reduce flat spots is a well felt brake pedal and driver training. The brake pedal should be solid and not soft to increase driver confidence.

Our FSAE Tire History and Tips[edit | edit source]

Choosing the right tire compound[edit | edit source]

As with most setup options in FSAE, there is no better substitute to going out, driving, and looking at the data that comes from the car. However — due to reasons outside of our control — we are unable to test every tire compound we wish. For this reason, we resort to both the Tire Testing Consortium (TTC) for actual real-world data from FSAE about tires, along with student-built models which help us better understand tires. (TTC page and Tire modeling page)

When comparing two tires, one should primarily focus on the peak FX and FY forces the tires generate, along with the sensitivity to pressures and temperature.

Peak forces are self-explanatory, as the higher forces a tire can generate, then the faster the car goes (in theory).

Ideally, a "good" tire would not change in FX or FY drastically with a change in tire temperature or tire pressure as these are factor that even though we can control them to a degree — they may change throughout the course of a test day or change depending on location (Atlanta vs. Michigan), changing the handling characteristics of the car if the tire is very sensitive to either tire temperature or tire pressure.

F25[edit | edit source]

The F25 uses 16x7.5-10 Hoosier R20 tires mounted to OZ Racing Formula Student Magnesium CL 10" wheels. The R20s were chosen over LC0s for their greater peak force in both FX and FY. Additionally, the R20s are less sensitive to temperature changes and camber adjustments when compared to the LC0s.