Tire

A tire refers to the ring of rubber around the wheel (or rim) that is in contact with the ground. Tires are the only link between a FSAE car in the ground and thus are extremely important (duh). For a tire alignment overview, check out suspension handbook geometry page.

Characteristics

Balance

In order to rotate smoothly a tire must have an even distribution of mass around its circumference. An unbalanced tire will vibrate. This can be corrected by applying weights on the wheel to balance it.

Centrifugal expansion

When a tire turns at a high rate of speed, it has centrifugal force. If a tire spins fast enough, the centrifugal force generated may be enough to increase the diameter of the tire through "pulling" on the rubber sidewalls. This is not a notable issue on FSAE cars.

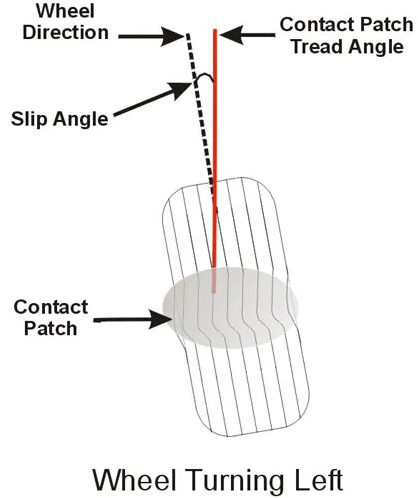

Slip angle

Slip angle is the angle between the direction a tire is pointing and the direction it is traveling. Slip angle results in a force perpendicular to the direction the tire is pointing called cornering force. Slip angle causes a deformation in the tire tread, which in turn acts as a spring. This "spring" has a returning force which is the cornering force. At low angles of slip, corner force increases linearly with slip angle. As the angle of slip increases, it will eventually reach a point at which the corner force increases non-linearly with slip angle. Finally, the tire will reach a peak cornering force and thereon after an increase in slip angle will decrease cornering force.

The ratio of slip angles for the front to rear tires determines the car's behavior in a turn. A ratio greater than 1:1 demonstrates understeer while a ratio less than 1:1 demonstrates oversteer. This ratio can be changed by modifying a car's roll center, spring rates, or anti roll bars relative front to rear.

Circle of Forces

Circle of forces is a way in which to visualize the forces acting between a tire and the road. It is a 2D visualization viewing the tire from the top, with the tire rolling on the xy-plane which acts as the ground. The y-axis is the direction of travel of the vehicle of which the tire is attached. The diameter of the circle is the maximum magnitude of lateral force the tire can generate. The diameter of the circle depends on the road surface, load, and condition of the tire, so basically the amount of friction available. In real life, the circle is usually an ellipse with the y direction being longer than the x.

In this example the tire is turned to the right. The tire is pointed in a different direction than the direction of travel and thus must slip. It generates a horizontal force (F) by the mechanism of slip. F is perpendicular to the wheel direction. The X component of the force is transferred through the suspension to the chassis thus causing the vehicle to turn right.

Relaxation length

Relaxation length describes the delay between a slip angle occurring and the time it takes for the corner force to reach a steady state. It can be calculated as cornering stiffness over lateral stiffness. Cornering stiffness is the ratio of cornering force over slip angle. Lateral stiffness is the ratio of lateral force over lateral displacement.

Spring rate

Yep. Tires are also springs. The spring rate of a tire is the k-constant of its vertical stiffness. The magnitude of the k-constant determines the tire vertical deflection under load. This is largely influenced by the sidewall stiffness and air pressure.

Contact Patch

A tire's contact patch is the area in which it is in contact with the ground. The contact patch of a tire is constantly changing due to different loads being put through the tire. The length to width ratio of the patch affects cornering behavior.

Force Variation

Lateral Force Variation

Radial Force Variation

Tangential Force Variation

Rolling Resistance

Rolling resistance is the transmission of energy into deforming the tire rather than being conserved. A rubber tire will deform as it rolls to match the road surface. This deformation however requires energy, which thus provides the resistance of the roll.

Load sensitivity

The load sensitivity of a tire is the way it behaves under load. Classical friction theory suggests the max horizontal force should be proportional to the tire's vertical load. This is not the case rather the max horizontal force that can be generated is proportional to the vertical load raised to the power of often between 0.7 and 0.9.

(add more to this)

Wear

Because the tire is experiencing friction as it rolls, it wears. This leads into the different types of extreme wear FSAE tires can experience.

Graining

Graining occurs when the rubber of a tire spreads or separates and then fuses back together with the heat generated by the tire. It creates an uneven surface and can damage the physical characteristics of the rubber. Graining is caused by excess friction and heat. It most often occurs during excess over or under steer when which the tire gets dragged in a direction without pointing that way thus causing shear on the rubber, tearing it up and creating heat.

How do I stop it

Just drive better ong (ill write this l8r)

Blistering

Blistering is when strips or chunks of rubber are detaching from the tire. Blistering occurs when the tire is extremely overheated. This heat causes the bonds holding the layers of rubber together to fail, thus causing detachment of large pieces.

How do I stop it

Usually, change your tire compound as the current one could be too soft for the conditions and is thus overheating.

Flat Spot

A flat spot occurs when a tire's brake torque force exceeds the tire's ground contact torque force thus leading to the tire to stop spinning while the car is still moving, thus slicing rubber off the contact patch.

Our FSAE Tire History and Tips

F25

The F25 uses ____ tires mounted to OZ racing magnesium wheels.