Anti-roll bar: Difference between revisions

JosephBamert (talk | contribs) →T-bar anti-roll bar: picture |

JosephBamert (talk | contribs) →What is right for me?: niclink |

||

| Line 51: | Line 51: | ||

Honestly just watch this <u>short IndyCar explanation</u>: [https://www.youtube.com/watch?v=IM05REDwEAs&t=23s INDYCAR's Anti-Roll Bar technology is next level] | Honestly just watch this <u>short IndyCar explanation</u>: [https://www.youtube.com/watch?v=IM05REDwEAs&t=23s INDYCAR's Anti-Roll Bar technology is next level] | ||

== Nic-Link == | |||

There is an ''evil'' third option for an anti-roll bar called a Nic-Link. Rather than twisting a piece of metal to act as a spring, a Nic-Link bends a metal bar at a predetermined kink. Realistically, the only reason you would use this is a strange packaging situation. The drawback of a Nic-Link is largely that the force concentrated in one area. This can easily lead to buckling. It also will likely raise your center gravity, weighs more than a T or U bar, and is not as adjustable. I really just wanted to add this here because it is weird. | |||

= What is right for me? = | = What is right for me? = | ||

Revision as of 14:17, 13 August 2025

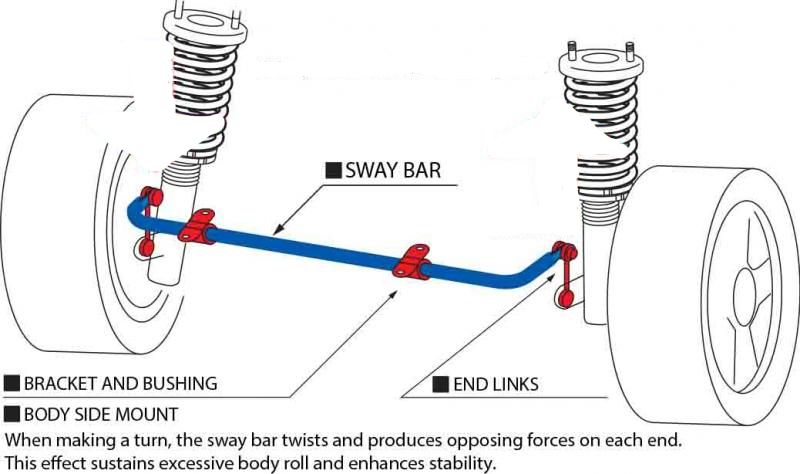

An anti-roll bar is suspension part that resists vehicle body roll, most often through the twisting of a bar. On a traditional anti-roll bar, laterally opposite wheels each have a drop links connected to the anti-roll bar. A blade style anti-roll bar resists relatively opposite suspension movement through the twisting of a blade.

What's the Point

A vehicle's body "rolls" during cornering due to the center of mass not being in the same location as the roll center. This creates a moment known as a roll couple. So why do we not just let the car body roll? In order for the aero package to work consistently well. A rolling body creates unequal sized gaps between the undertray and the ground creating adverse wakes that decrease downforce while increasing drag. Additionally, while piloting a car with significant body roll the driver will feel disconnected from the tires.

Anti-roll bars change the vehicle's roll stiffness. A change in an axle's roll stiffness further changes the distribution of load front-to-rear during lateral load transfer. Anti-roll bars do not change the load distribution left-to-right. Using anti-roll bars to change front-to-rear load distribution allows us to change the balance of the car during lateral load transfer (aka "mid"-corner).

| your wish | your genie |

|---|---|

| to reduce understeer | stiffen rear anti-roll bar or soften front anti-roll bar |

| to reduce oversteer | soften rear anti-roll bar or stiffen front anti-roll bar |

How it works

The beauty of anti-roll bars is that they only affect the dynamics of the suspension when there is a relative difference between the left and right suspension positions. Therefore, with the use of an anti-roll bar the dynamics of roll can be isolated.

An anti-roll bar does nothing during pitch and heave because when both sides of the suspension are compressed, the anti-roll bar does not twist and therefore provides no suspension resistance. When anti-roll bars twist they are essentially acting as springs.

U-bar anti-roll bar

A U-bar, or traditional, anti-roll bar connected to either side of the suspension by drop, or end, links. The anti-roll bar is also fixed the chassis at 2 points. When the outside suspension compresses and the inside extends, the anti-roll bar twists, therefore reducing the extent which the inside suspension extends and the extent which the outside compresses. This keeps the car's body more horizontal thus body roll has been reduced.

Note that on two identical vehicles aside from an anti-roll bar, when experiencing an equal lateral acceleration, the outside suspension of the vehicle with the anti-roll bar will compress less than the vehicle without. Essentially, the anti-roll bar forces the left and right suspension to "share", meaning the outside suspension is compressed less and the inside is extended less.

The stiffness of the anti-roll bar is inversely proportional to drop link length. To calculate an estimated torsion stiffness of a traditional anti-roll bar use the following:

- karb is the torsional stiffness of the anti-roll bar

- D is the diameter of the anti-roll bar

- G is the anti-roll bar's material's shear modulus

- l is the anti-roll bar's effective length

There are other equations that are probably better lowkey. The torsion stiffness can be used to calculate roll stiffness.

The advantage of a U-bar is its simplicity relative to the T-bar. It can still be adjusted by changing drop link length. There is also less moving parts and not a need for rocker-arm suspension. Because it most often goes under the chassis, U-bars often decrease the center of gravity. The disadvantage of the U-bar is that it is often heavier than a T-bar and there are aerodynamic penalties as it is not within the bodywork.

T-bar anti-roll bar

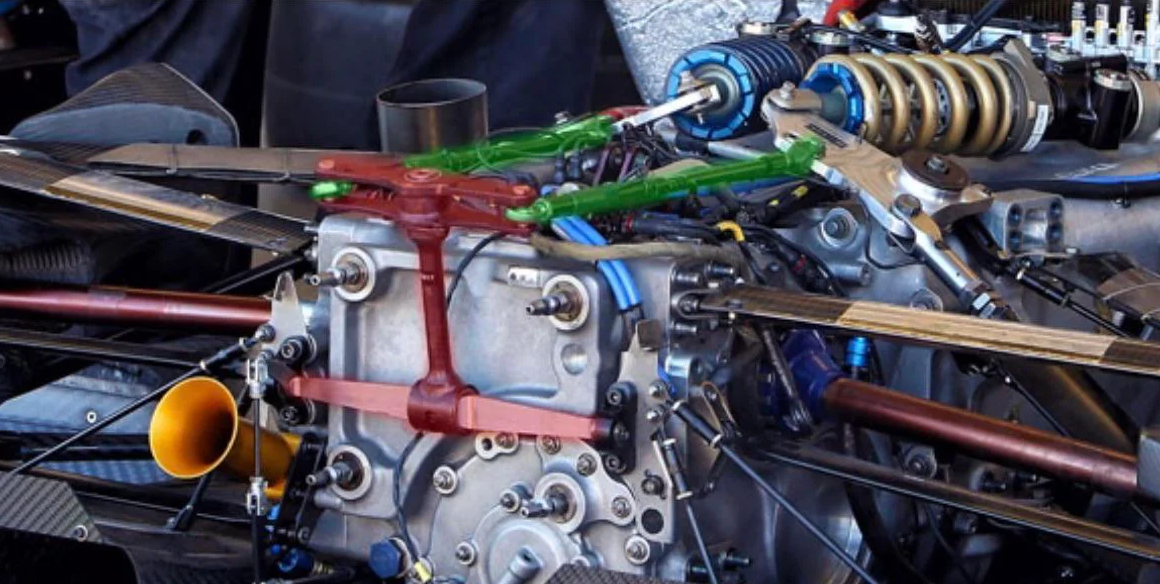

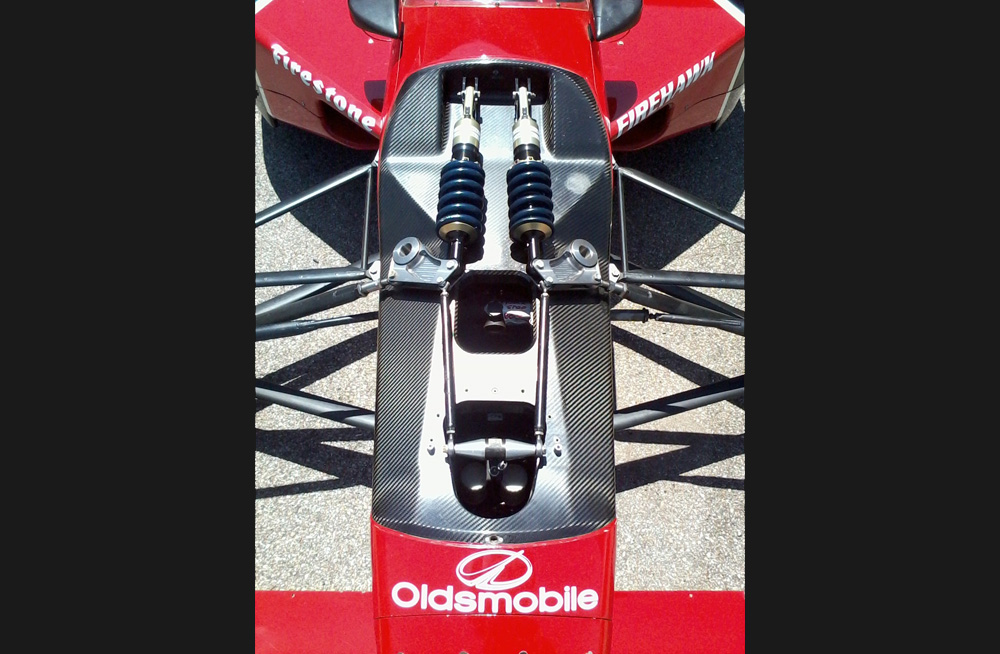

A T-bar anti-roll bar is also connected to either side of the suspension, but unlike traditional anti-roll bars they are often connected to rocker arms. When both springs compress, the T-bar is not twisted; the assembly just moves forward/backwards. However, when there is relative movement between the springs, the T-bar is twisted therefore reducing the extent which the inside suspension extends and the extent which the outside compresses. T-bar anti-roll bars often twist a blade. A blade refers to an object offers high resistance to a torque in one orientation but rotated 90 degrees it has a lesser resistance to torque. For example, if you hung a knife laying on its side off an edge and pressed on the end of the blade, it would bend easily. However if you rotated the knife so that it was upright and the blade was vertical and then pressed on the end of the blade it would have a much increased difficultly in bending.

The advantage of the T-bar anti-roll bar is packaging, weight, and adjustability. Because the anti-roll bar is often connected to the rocker arms, it is often easy to transfer the twisting force to a "far away" blade allowing for better packaging and an opportunity to lower the center of gravity. This additionally allows for the anti-roll bar assembly to be completely under body work thus reducing drag. The weight advantage is largely due to taking advantage in the coilovers proximity to each other allowing for a much smaller anti-roll bar that does not have to span almost the entire tract width.

Because a non symmetrical blade is being twisted, depending on its orientation its effective spring constant changes. Thus the anti-roll bar's effective stiffness can be changed quickly, sometimes even by the driver.

Honestly just watch this short IndyCar explanation: INDYCAR's Anti-Roll Bar technology is next level

Nic-Link

There is an evil third option for an anti-roll bar called a Nic-Link. Rather than twisting a piece of metal to act as a spring, a Nic-Link bends a metal bar at a predetermined kink. Realistically, the only reason you would use this is a strange packaging situation. The drawback of a Nic-Link is largely that the force concentrated in one area. This can easily lead to buckling. It also will likely raise your center gravity, weighs more than a T or U bar, and is not as adjustable. I really just wanted to add this here because it is weird.

What is right for me?

What should first be determined is do you really need an anti-roll bar. Assuming you have a driving car without a roll bar here are some questions you should ask:

- are the drivers happy with the over/understeer balance?

- are you ready for the weight gain?

- If you are switching to a anti-roll bar so you can use softer springs?

- if not then instead of a roll bar consider higher rate springs to increase roll resistance

- if so then talk to aero and make sure running softer springs wont cause excessive scraping

- Did you run simulations with and without an antiroll bar to compare theoretical data?

- Did you run simulations with only a rear ARB?

- Only a front?

- With the same roll stiffness and softer springs?

- Are you ready to design your packaging, suspension, chassis and body around the ARBs?

- Do you need ARBs front, rear, or both?

Now that you know you want an anti-roll bar, U or T? It essentially exclusively depends on your suspension and chassis setup. The fact of the matter is, the suspension setup and chassis must be designed around the anti-roll bar. A T-bar needs chassis mounts for the blade, ideally horizontal coilovers, and room to fit it all within the aerodynamic body. A U-bar needs 2 body mounts as well as drop links connecting it with the suspension.

If you are starting from scratch, I would recommend the use of a T-bar in the front because of the aerodynamic benefits, ease of adjustability, and lesser mass. In the rear due to the engine being in the way, there are many trade offs between the T and U bars thus it depends on what fits.

History

F25

The F25 despite being aerodynamically sensitive to roll did not use an anti-roll bar. Additionally, the F25 suspension was mounted vertically rather than horizontal therefor not allowing for the use of a T-bar.

F26

I havent checked yet.

F27

As of 2025 I am researching whether the F27 should implement an anti-roll bar.