Damper: Difference between revisions

JosephBamert (talk | contribs) →How it works: added damping ratio info, need more |

JosephBamert (talk | contribs) →Damping Ratio: pic |

||

| Line 9: | Line 9: | ||

== Damping Ratio == | == Damping Ratio == | ||

[[File:Damp.jpg|thumb|512x512px]] | |||

A system can be under damped, critically damped or over damped. This is determined by the system's damping ratio, zeta. Zeta is: | A system can be under damped, critically damped or over damped. This is determined by the system's damping ratio, zeta. Zeta is: | ||

| Line 28: | Line 29: | ||

== What-ifs == | == What-ifs == | ||

This is general guide to push you in the right direction when tuning dampers. Do not take this as gospel and make sure to consider changing other attributes of the car such as spring rates or alignment too. Although, dampers are a good thing to change for fine tuning. | This is general guide to push you in the right direction when tuning dampers. Do not take this as gospel and make sure to consider changing other attributes of the car such as spring rates or alignment too. Although, dampers are a good thing to change for fine tuning. (i dont think the table is correct rn) | ||

{| class="wikitable" | {| class="wikitable" | ||

|+ | |+ | ||

Latest revision as of 14:35, 11 August 2025

A damper is a hydraulic device placed most often within a spring that will convert the kinetic energy of a system into another form, often heat. This is done by forcing a hydraulic fluid through small passageways, thus reducing the springs kinetic energy. Dampers are described with stroke (linear distance) and damping coefficient (force per velocity). Many dampers used in FSAE have 4 different damping coefficients.

How it works[edit | edit source]

Springs are an oscillating body that store force. In a perfect system, springs would oscillate forever. Having almost forever oscillating suspension on a race car is as useful as safety glasses in a nuclear explosion. Thus, the system needs to be damped. Damping is a "decrease in the amplitude of an oscillation as a result of energy being drained from the system to overcome frictional or other resistive forces." In FSAE we damp our springs with a linear damper (or dashpot).

A linear damper consists of a main body, a piston with holes in it, and a hydraulic fluid. The piston sits inside of the main body and moves through the hydraulic fluid. In order for the piston to move through the hydraulic fluid when compressed or extended, the hydraulic fluid must pass through the holes of the piston. Thus, the damper is exerting a force in the opposite direction of the motion. This damps the springs movement and allows it to settle. The force a damper exert is proportional to the velocity. The damping coefficient determines the force a damper exerts. In FSAE dampers, the damping coefficient can be different in compression (bump) and rebound. The damping coefficient is changed by mechanisms in the damper that allow less or more oil through the piston. Nitrogen is used to keep the hydraulic fluid pressurized.

Dampers do not change a spring's rate because a damper only exerts force when it has velocity. Therefore, a spring-damper system in the presence of a constant force will compress the same length in the long run as a lone spring. However, in the presence of a quick force, a spring-damper system will not compress the same length as a lone spring. So, despite not changing an axle's roll stiffness, dampers can give the suspension a feeling of more or less compliance under non-steady-state conditions. Dampers essentially change the speed at which a car rolls or pitches, but not the extent.

Damping Ratio[edit | edit source]

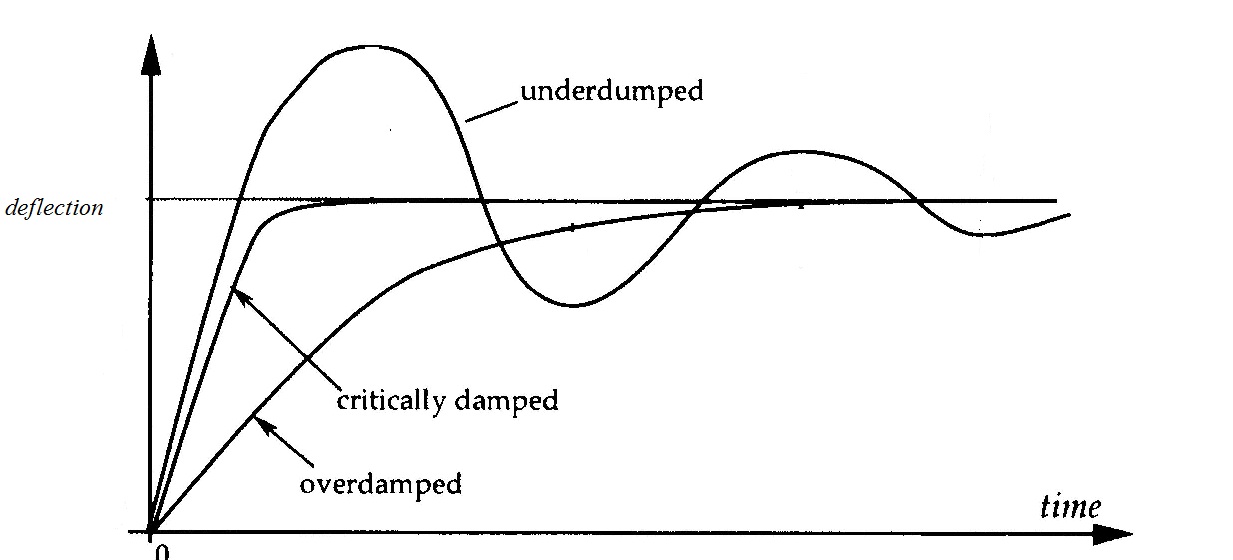

A system can be under damped, critically damped or over damped. This is determined by the system's damping ratio, zeta. Zeta is:

For a simple mass-damper-spring system the system's critical damping is:

Where k is the spring constant and m is the sprung mass,.

An under damped system will overcorrect, leading to an overshooting of the equilibrium position. An over damped system will correct too slowly. An overdamped rebound setting can lead to jacking down; where a bump compresses the suspension, but the system does not return to an equilibrium position before further bumps occur, thus leading to the suspension compressing more and more. A critically damped system will return to the equilibrium position in the shortest amount of time without overshooting.

Tuning[edit | edit source]

Most FSAE dampers have 4 tunable attributes: compression, fast compression, rebound, and fast rebound. Each of these attributes are able to have their damping coefficients changed. The "fast" settings change the damping attributes for situations in which the damper is compressed or extended at a rapid rate, such as hitting a sausage kerb or a white-water pothole. The terminology concerning dampers is often extremely confusing and contradictory, so in this page we will be using the following terminology: Lowering the damping force means lowering the resistance the damper provides to the spring. This makes the spring and suspension move faster.

Damper Dyno[edit | edit source]

A damper dyno is a machine used to measure a damper's damping force over a range of velocities. The damper is tested throughout its range of travel. On adjustable dampers, their damping force is measured with rebound and compression settings on the lowest and highest setting to provide the damper's force range.

What-ifs[edit | edit source]

This is general guide to push you in the right direction when tuning dampers. Do not take this as gospel and make sure to consider changing other attributes of the car such as spring rates or alignment too. Although, dampers are a good thing to change for fine tuning. (i dont think the table is correct rn)

| What-if | Damper change |

|---|---|

| driver complains of turn-in understeer | reduce front compression damping force |

| driver complains of turn-in oversteer | increase front compression damping force |

| driver complains of understeer on corner exit | increase rear compression damping force |

| driver complains of oversteer on corner exit | reduce rear compression damping force |